Our services

OmegaChem develops and synthesizes molecules intended for biological tests for its customers through research and development contracts.

Custom Synthesis

- FFS or FTE

- Custom synthesis

- Assess project status and identify chemistry issues

- Resolve chemistry issue

- Enable core synthesis

- Enable analog synthesis

- Project management

Process Chemistry

Our process development group is composed of highly skilled and creative organic chemistry scientists who have significant experience in synthetic chemistry and process development of drug candidates, intermediate compounds, and building blocks.

Our services include the following:

- Thorough evaluation to determine deficiencies in the original synthetic route

- Exhaustive retrosynthetic analysis of the target compound to provide a thoughtfully different approach

- Establishing a new route which is safe, scalable, environmentally friendly, and cost effective

- Execution of the new approach and timely delivery of the requested material that meets client’s specifications

- Ability to produce multi-kilogram batches of non-GMP advanced synthetic intermediates or APIs

- Identification of impurities and their synthesis when required

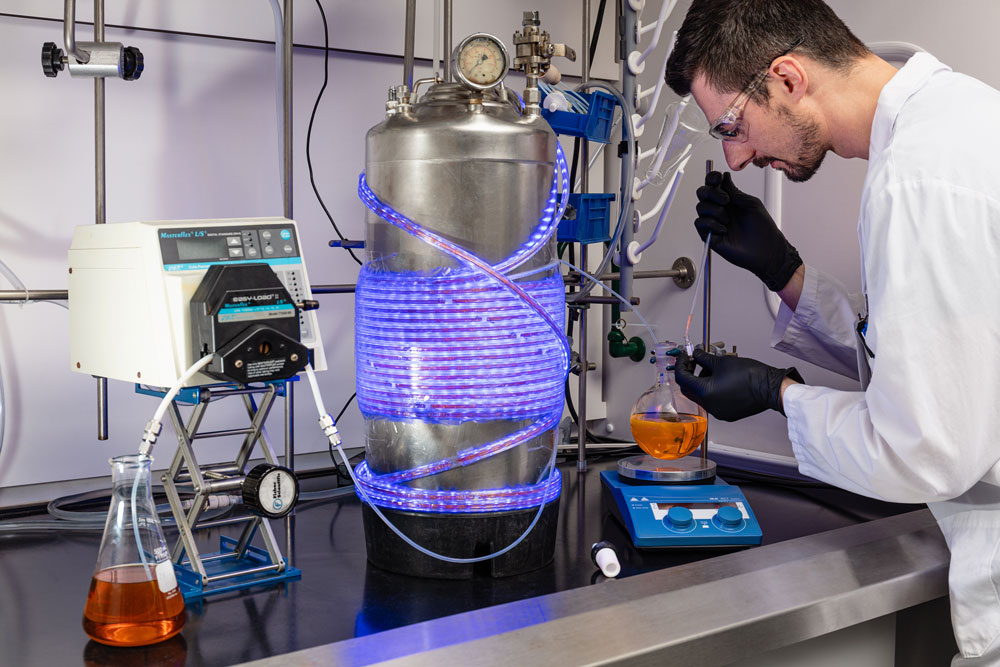

OmegaChem process chemistry team experienced chemists exploit the potential of cutting-edge technologies to work more efficiently. Our flow chemistry systems offer precise control and high-throughput reactions, while our photochemistry and electrochemistry capabilities allow for unique synthetic pathways. Our state-of-the-art cooling systems provide optimal conditions for even the most temperature-sensitive reactions. Experience the benefits of large-scale chemical synthesis with OmegaChem‘s innovative technologies.

Our process chemistry team uses state-of-the-art chemistry methodologies and creative design of synthetic routes to develop processes suitable for the larger-scale manufacturing of drug candidates. We have the capability to prepare complex, challenging molecules in house, accommodating multi-kilogram requirements as needed.

Our scalable equipment includes the following:

- Glass reactors up to 50 L (temperatures from -78 °C)

- Hastelloy reactors up to 7.5 L (pressure up to 200 psi) with heating/cooling systems

- Process safety assessment (Thermal Screening Unit)

- CombiFlash Torrent System for large scale purification

- Preparative SFC for complex purification up to 400 mL/min & 1 kg scale

To ensure the smoothest possible transition, OmegaChem follows a proven transfer process.

Our transfer process includes the following:

- A detailed report/technical transfer package suitable for a commercial scale CMO

- Detailed analytical conditions to ensure proper reaction monitoring and identification of product and impurities

- Assistance with implementation of the new process at the alternative facility.

We work as an extension of our customer’s internal R&D teams providing high quality services at competitive rates and meeting project timelines.

R&D Contract

Through an outsourcing contract, our scientists develop one or more complex products conditioned by several variables such as feasibility, chemical complexity, number of development steps, scientific uncertainty, cost of raw materials, and pharmacological profile. Our scientists are supported by a modern analytical department whose services include preparative SFC purification capabilities.

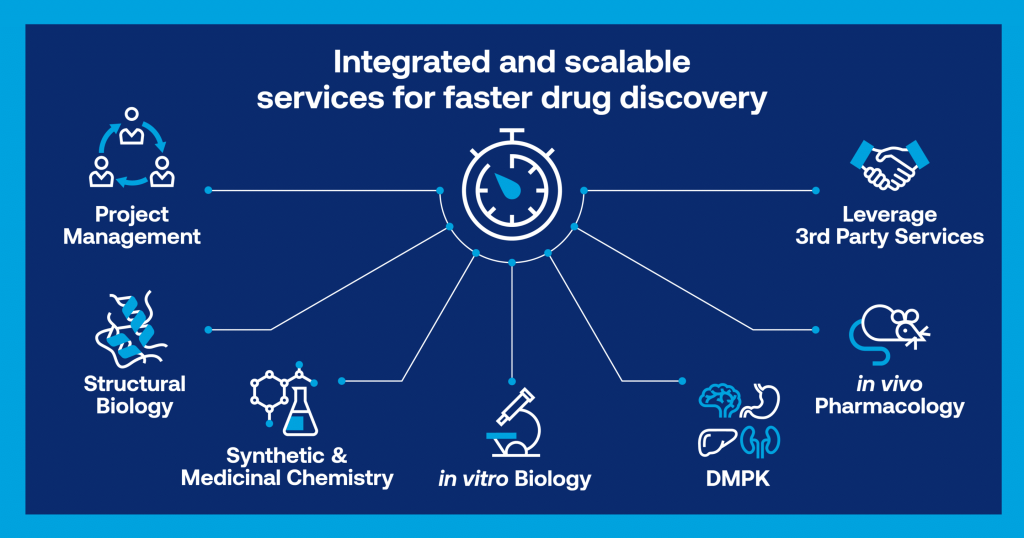

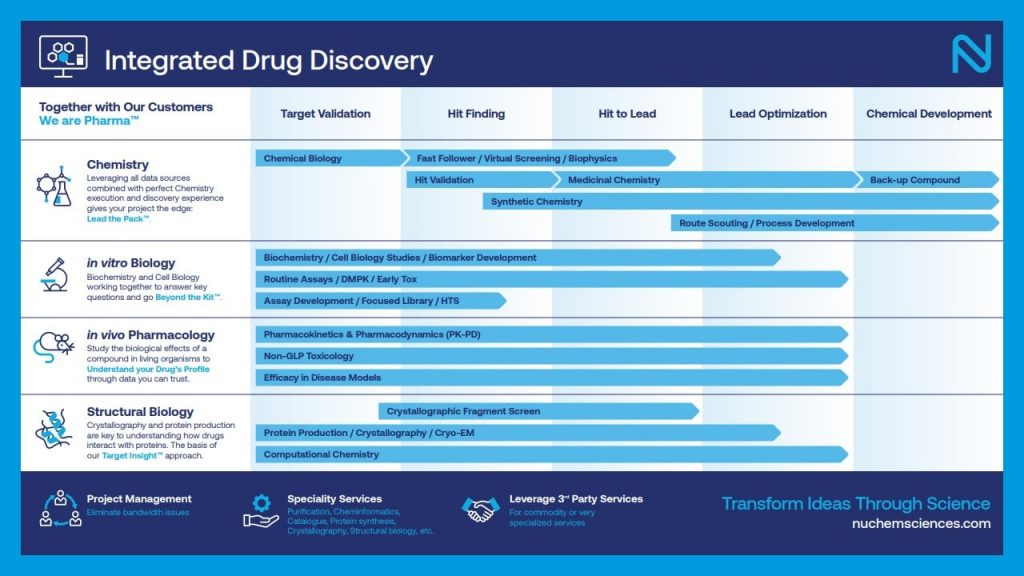

NuChem Integrated Services

A new era brings a new reality. Together with our customers: We are Pharma™

Upcoming milestones or deadlines? Cover more ground faster with a fully integrated team of experts and services co-located in Canada. See how we can fill the gaps in your projects.

Visit nuchemsciences.com to discover how NuChem propels the dream of a potential breakthrough into a workable reality.

Subscribe to our newsletter!

Receive OmegaChem news by subscribing to the NuChem Sciences newsletter.